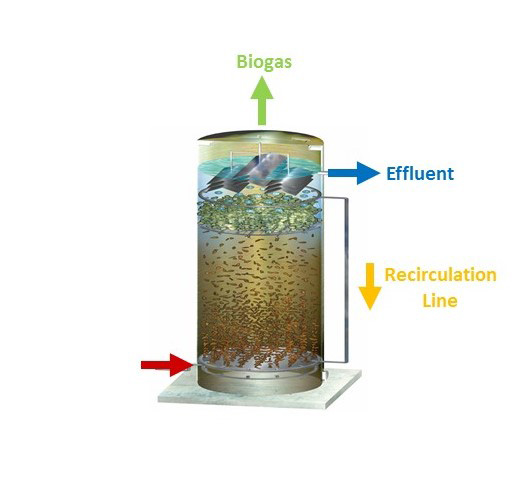

1: Wastewater is pumped from a holding tank through a sparger distribution system which normalises the upflow velocity across the base of the reactor. In the reactor the wastewater passes through a fluidised bed of anaerobic microbes where organic components are converted into methane and carbon dioxide.

2: The effluent is then passed through a fixed film filter in the upper section of the reactor, which acts as a polisher to generate high quality effluent in terms of reduced TSS and COD content.

3: Biogas naturally separates from the liquid and rises to the top of the reactor. The biogas is tapped at the top of the reactor where it is transferred to a condensate pot for pre-treatment ready for storage.

4: Treated wastewater exits the reactor above the fixed film filter and is ready for discharge to sewer or local waterways.

5: The solution reduces chemical oxygen demand levels by 80% and total suspended solids (TSS) by 50%. It reduces sludge by 90% compared to other treatment solutions which have no reductive effect on sludge generation.